Wastewater

The Untapped Water Resource in Your Business

ADVANCING THROUGH INNOVATION

Innovative Equipment

Engineered into a Robust Process

Avoid these Mistakes when Integrating Circular Water into Your Process:

I. Complicated Process

Complicated process designs are the result of trying to solve modern problems with conventional methods.

- Equiment intensive due to many treatment stages

- High space & surface requirements

- High energy demand

- to transfer water in between treatment stages

- to operate the various treatment stages

- 24/7 manpower needs

- High maintenance time & cost

- High amounts of chemicals

- High sludge production

- Hazardous waste disposal cost & management

- Hazardous work environment (occupational health & safety risks & management)

II. Conventional Technology

Sandfilters, Mediafilters, Polymeric membranes and other conventional technologies are consumables with many drawbacks.

The main advantage of organic membranes is the low capital expenditure due to low manufacturing costs. Polymer membrane technology is especially suitable for water desalination processes through reverse osmosis. But less suitable for industrial wastewater.

- Conventional Polymer Membrane drawbacks

- Low recovery rate = Low lifetime & frequent exchange

- Low chemical resistancy & Limited pH range

- Low temperature range (usually < 45 deg.C)

- Low potential for energy recovery

- Sensitive to water hardness

- High OPEX

- Mislead by Membrane Pore Size

- ULTRA - FILTRATION:

- Separation of colioids > 20'000 Dalton

- Separatiom of solids > 0.01 Micron or 30 Nanometer (often confused with Nanofiltration)

- ULTRA - FILTRATION:

III. Wrong Investment Priority

A low CAPEX goes hand in hand with a high OPEX. A long term apporach to managing your water is one key to success.

Sourcing of water & disposal of wastewater is a difficult and costly problem, facing evermore strignent regulations.

Thus, minimizing effluents for disposal as much as possible through recycling & reuse of the water back into the process makes sense.

Therefore, the water treatment technology has to be chosen to efficiently operate as an integrated part of your process, which is, on long term.

You know Your Business - We know Ours.

There is no "one size fits" all or "off the self system" to efficiently treat your wastewater into a quality suitale for reuse.

We analyze your water & your needs to design a taylored treatment process.

Why Does It Work?

Because it Combines Expertise with a Robust & Proven Process

I. Right Process & Technology

Chosing The Wrong Technology Has Major Impacts On Viability & Efficiency.

- Integrated Project Delivery with a 360 degree aproach

- Feasibility Study

- Process design from watewater input to purified water output for reuse

- Project commissioning

- Operation & Maitenance

- Your advantages:

- Few treatment stages & low equipment needs

- Compact & low surface requirements

- Low energy demands / Energy recovery

- Weekly regular maintenance & checkups

- Low maintenance time & cost

- Low amounts of chemicals

- Low/No sludge production

- Low quantities of waste disposal / Zero Liquid Dicharge options

- Safe work environment (occupational health & safety risks & management

II. Right Membranes

Robust Ceramic Membrane Technology Efficiently At Work for You

- Ceramic Membranes benefits

- High recovery rate = High lifetime

- High chemical resistancy & pH range 0 to 14

- High temperature range (usually < 100 deg.C)

- High potential for energy recovery

- Excellent water softening capacity

- Low OPEX, fully automated with CIP

- Informed of Membrane Pore Size

- NANO - FILTRATION:

- Separation of Dissolved Solids > 200 Dalton

- Separatiom of solids > 0.001 Micron or 1 Nanometer

- NANO - FILTRATION:

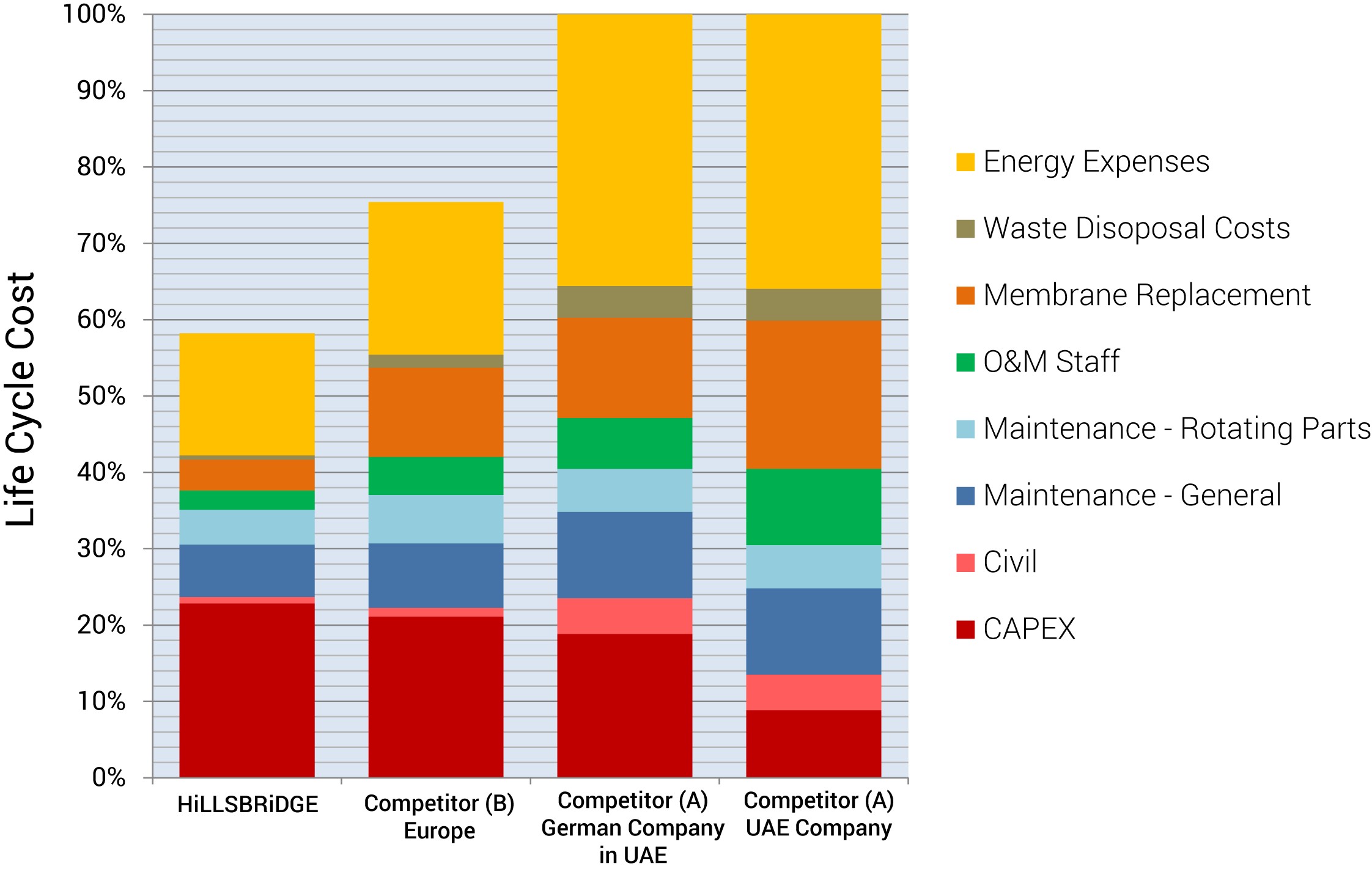

III. Right Investment Priorities

A Decision Making Basefd On A Life-Cycle Cost Approach

Integrating water treatment into your business is a long term project with the aim to create long term benefits.

- Impact of CAPEX on Life-Cycle Cost

- Over the project life, CAPEX amounts only 10-30% of the total cost.

- Opex is the major cost factor.

- Cost Factors to concider

- Membrane replacement

- Labor cost for daily operation & maintenance

- Chemical cost

- Downtime cost due to repair works

- Energy cost

- Waste disposal cost (sludge, chemicals, ect.)

- Non-Cost considerations

- Space requirements

- Odor emissions

- Health hazards due to open systems

Don't be Left Behind:

Apply For Your Initial Assessment Today!

Innovative Water & Wastewater Treatment Systems Integration

© 2024 Hillsbridge Global Water FZCO. All rights Reserved