Ornamental & Recreational water filtration has changed

Swimming Pool Owners

The immediate advantage of ceramic microfiltration technology over established sand filters is the improved retention of micro-organisms. These pathogens, such as Cryptosporidium and Giardia, may be resistant to chlorine and can cause harm to swimmers. Moreover, free chlorine in pool water may react with substances such as skin microbes and sweat to produce chloramines, which create unpleasant odors and cause irritation of the eyes, skin and respiratory system. It is generally accepted that chloramine-generating chemical reactions occur at the dirty layer trapped in the filtration medium. Numerous swimming pools have failed routine safety inspections due to inefficient and outdated pool filtration systems, resulting in expensive pool closures. There have also been a number of reported instances of lifeguards and employees with respiratory diseases linked to consistent exposure to indoor pool environments.

Recreational Pool Owners

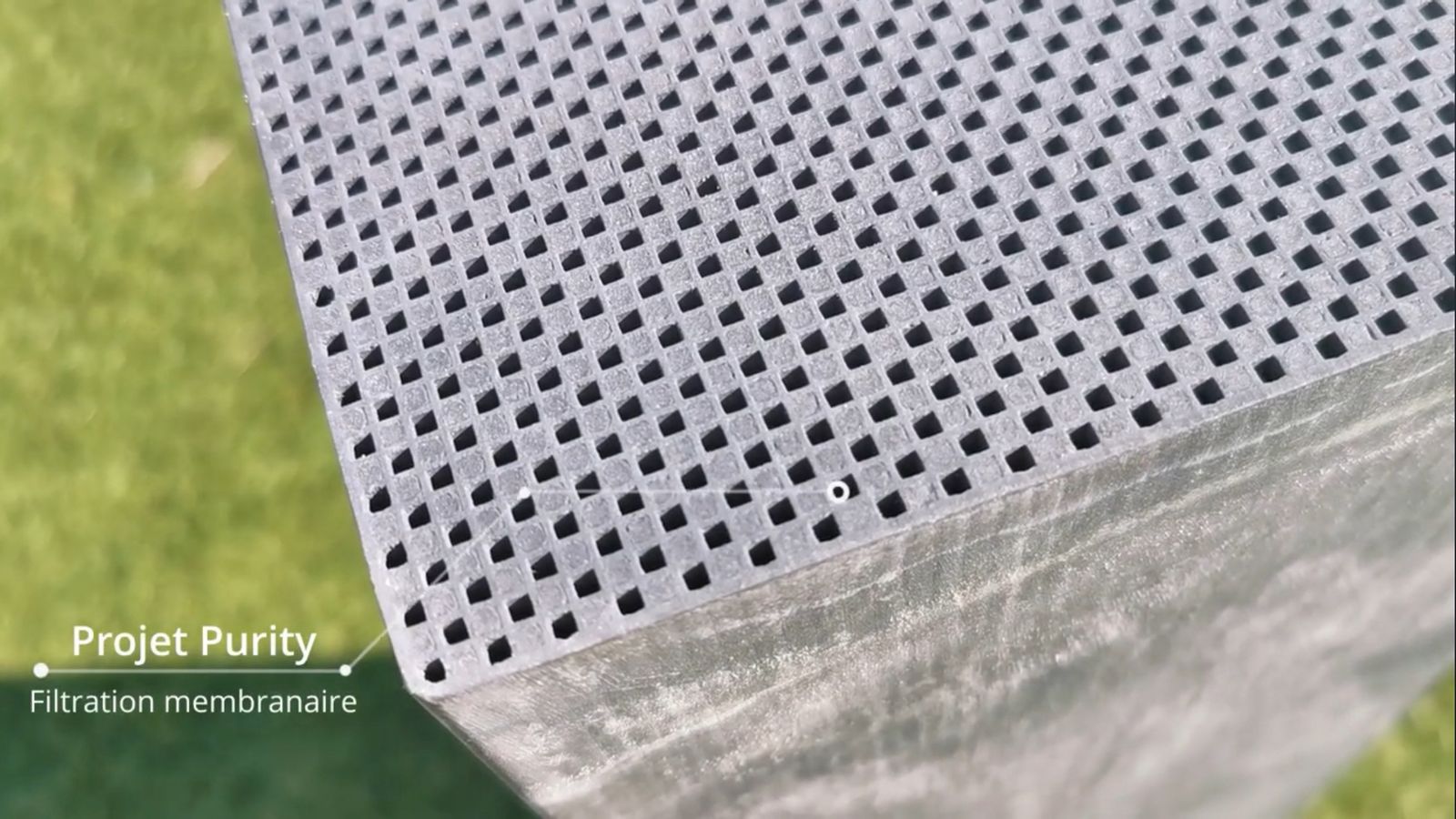

Ceramic microfiltration membranes offer a novel, cost-effective solution to these issues. Chloramine reduction is achieved thanks to very frequent, fast (3 to 5 seconds) and low water consumption backwashes (30 to 60 liters/ membrane), which are performed 4 to 6 times a day. As a consequence, the dirty layer retained in the membrane is quickly removed, leaving less time for the chloramine- and trihalomethane-forming reactions to occur.

Filtration of various harmful microorganisms has been measured using ceramic membranes with demonstrable results. Cryptosporidium removal is ensured with a proven efficiency of over 99.996% using Saint Gobain’s HiFlo ceramic membrane, which has also been tested for legionella removal with a success rate of up to 99.96%, without the use of flocculants.

This increase in water quality and safety does not represent a commensurate increase in costs.

- Ceramic membranes boast reduced water and power consumption compared to sand filters.

- Water usage for backwash operations, for instance, can be decreased by as much as 70%. As a consequence, the costs of water renewal heating and chemical treatment can be significantly lowered.

- Pools can be operated at the minimum required level of chlorine with very low risks of pathogen outbreaks.

- Crystar® filtration membranes can be integrated into compact housings to fit existing technical spaces, reducing the cost of renovations for space saving filtration.

- Finally, the operation of Crystar® filtration systems requires a low level of maintenance, since backwash operations can be automated and the filtration medium does not need to be replaced.

Tailored water treatment to specific areas of application

We don't sell equipment.

We provide integrated solutions.

H2O - Water - Agua - Eau - Wasser - Acqua - ماء

Water has become a focus, globally. Concerns about water scarcity and quality are on the rise. A more circular and therefore more sustainable economy requires valuing wastewater for its potential, rather than discarding or ignoring it.

More than just an alternative source of water, safe wastewater management could help protect our ecosystems and give us clean water, energy, nutrients and other recoverable materials.

- Join the Flow -

Innovative Water & Wastewater Treatment Systems Integration

© 2024 Hillsbridge Global Water FZCO. All rights Reserved